Mold Temperature Control Pipe Cleaning Machine

SUKATTOSU/WATER REAMER

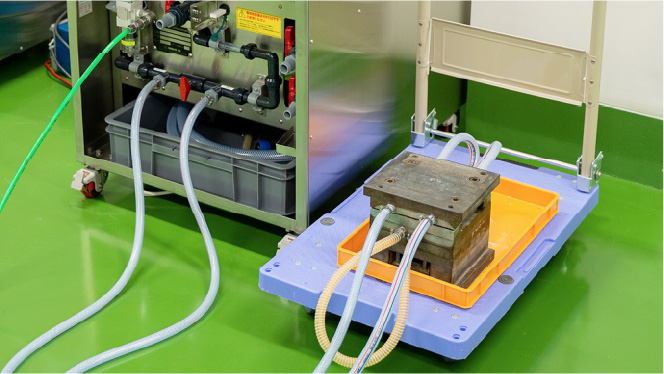

The SUKATTOSU/WATER REAMER is a cleaning machine that automatically completes the treatment of molds from cleaning to corrosion prevention.

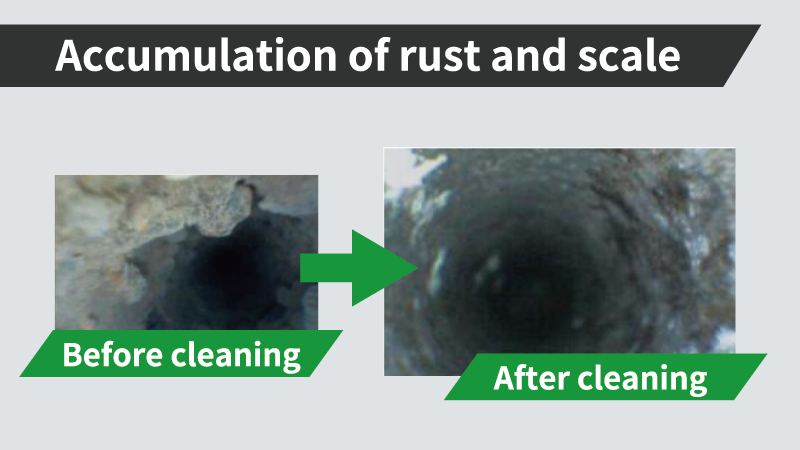

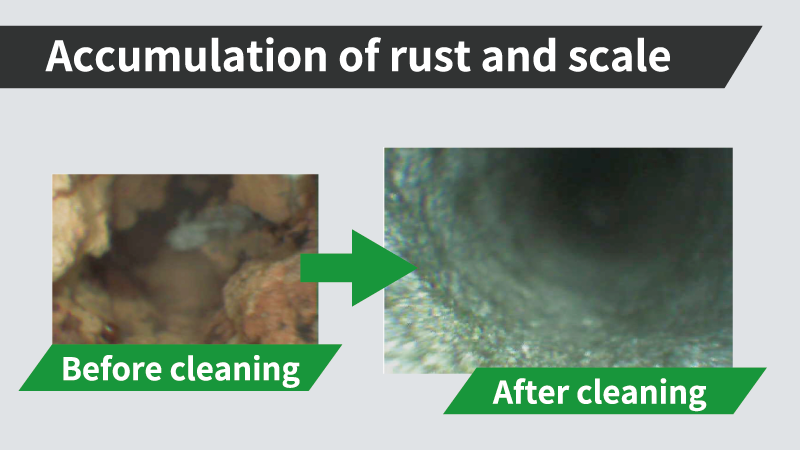

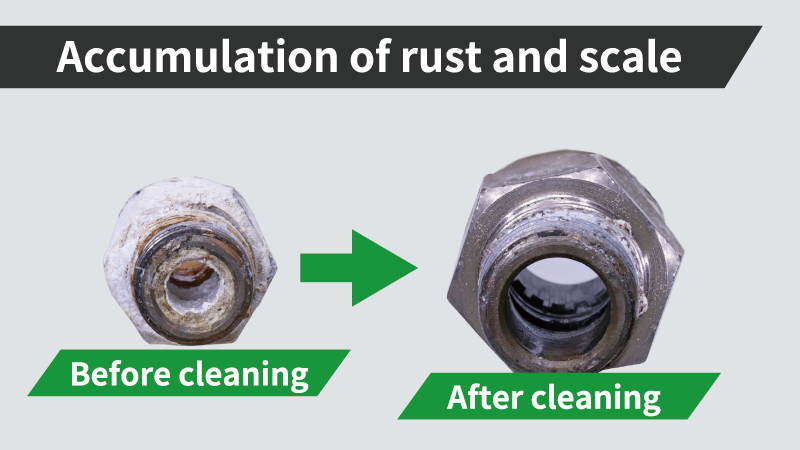

The process of dissolving and removing rust formed inside mold temperature control pipes and the layers of “scale” generated from impurities in the water,

as well as drying and corrosion prevention treatment, is completed in one operation.

-

Saving time and labor

No need to

disassemble molds

-

Preventive maintenance

An anti-corrosion film

is formed after cleaning

-

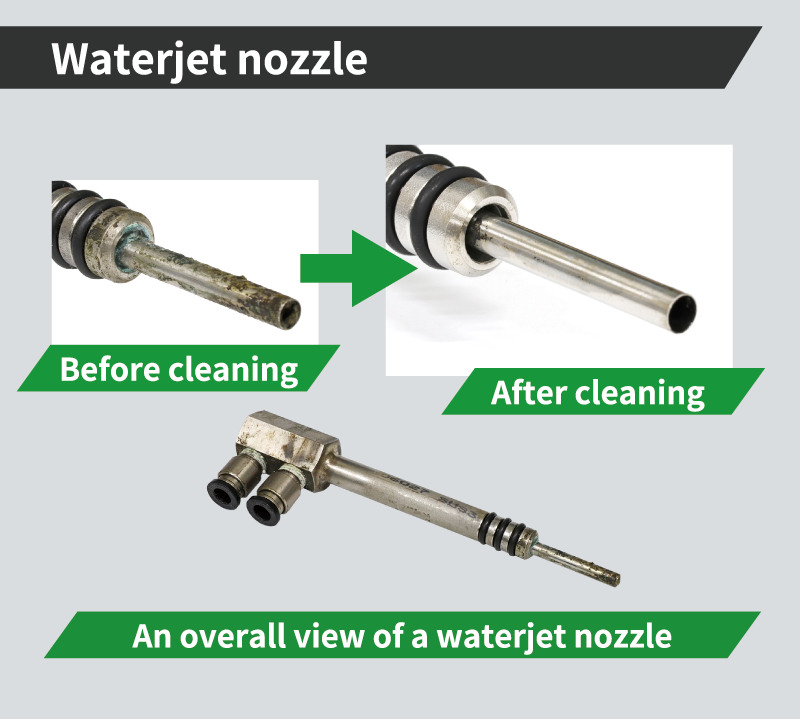

Powerful cleaning

Complex shapes can

also be handled

POINT

Conventionally, molds are disassembled and each of the pipes is cleaned by hand. In the cleaning work, the insides of the temperature control pipes are scraped with a bar or drill.

The SUKATTOSU/WATER REAMER can clean all of a pipe without the molds being disassembled.

An anti-corrosion film is formed after the cleaning to make the molds resistant to corrosion. The machine is especially suitable for pipes right after the completion of a new model or before molding as well as 3D temperature control pipes.

- Introduction of SUKATTOSU/WATER REAMER

-

The SUKATTOSU/WATER REAMER can dissolve and remove rust and scale in temperature control pipes without disassembling the molds.

Examples of cleaning

Cleaning ExampleThe operation time is shortened substantially with no need to disassemble the molds.

An anti-corrosion film is formed after the cleaning of molds to make them resistant to corrosion.

Catalog Download

Product Q&A

Product Q & AWhat are the features of the SUKATTOSU and the WATER REAMER?

It dissolves and removes rust and scale (layers generated from the accumulation of impurities in the water) without discharging sludge. Cleaning and the formation of an anti-corrosion film can be completed at the same time with only one type of cleaning solution.

Which materials cannot be cleaned?

They cannot clean aluminum, zinc and their alloys.

Can they clean molds without disassembling them?

It is possible. They perform cleaning, drying and anti-rust treatment in a single process without the disassembling of the molds.

Can they also clean 3D shaped pipes manufactured by metal printers?

Yes, it is the greatest strength of these machines. We recommend that they be used for preventive maintenance before molding and casting because they form an anti-corrosion film.

What cleaning solution is used?

A specified acidic anti-rust agent we have developed and manufacture.

Are there any problems for O-rings?

While most of the O-rings used in molds are made of acid resistant materials such as nitrile and silicon, it is necessary to identify their material before cleaning.

What is the difference between the SUKATTOSU and the WATER REAMER?

The size of applicable molds is different. While the WATER REAMER is for small molds, the SUKATTOSU can be applied to die-casting and other large molds.

Are they sold outside Japan?

There are representatives in the United States, Mexico, South Korea, China, Taiwan, India, Thailand, Indonesia, the Philippines, Vietnam, Malaysia, and other countries. In some countries, field demonstrations are available. Please contact us.

Lineup

LineupThe product specifications of the SUKATTOSU/WATER REAMER

- SUKATTOSU

-

■The machine can also handle large resin molds and die-casting molds.

■The molds do not need to be disassembled and labor spent cleaning and drying can be saved.

■Cleaning and corrosion prevention treatment can be completed in one operation.

■The condition of the temperature control pipes and the cleaning effect are quantified with the flow meter installed as a standard feature.

■It can also handle the complex 3D pipes of molds.

- WATER REAMER Alternate circulation type

-

■Improve detergency by circulating cleaning solution alternately.

■Make it compact keeping the same cleaning ability.

■Save labor for the process from cleaning to drying without disassembling molds.

■Complete cleaning and anti-rusting in one process.

■Check the condition of cooling pipes and cleaning effect by the values

with flowmeter as standard equipment.■Can clean mold parts of complicated 3D pipes.

- WATER REAMER

-

■This model is more compact but with the same level of cleaning power.

■The molds do not need to be disassembled and the labor spent cleaning and drying can be saved.

■Cleaning and corrosion prevention treatment can be completed in one operation.

■The condition of the temperature control pipes and the cleaning effect are quantified with the flow meter installed as a standard feature.

■It can also handle the complex 3D pipes of molds.

Products customized to meet customers’ requirements are available

Catalog Download

FreeRequest documents / Request for a demonstration

FreeRequest documents

Request for a demonstration

We support you with a demo machine

for free anywhere in Japan.

Online demonstration are also available for free!