Mold Cleaning Machine

CLIPIKA ACE

The CLIPIKA ACE thoroughly removes stubborn stains on molds without using any organic solvents.

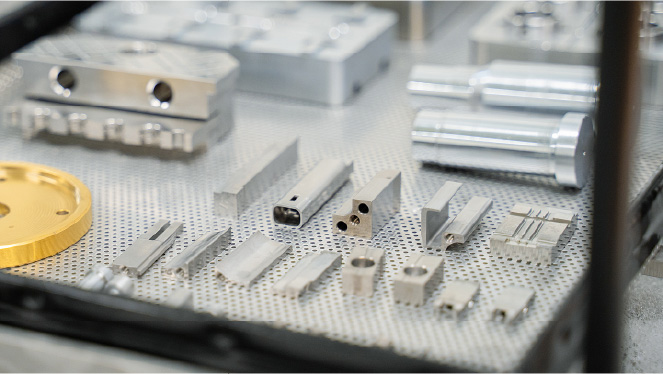

It can also clean multiple mold parts of various shapes at the same time to help solve labor shortages.

-

Saving time and labor

Multiple pieces can

be cleaned at the

same time

-

Safety and security

No organic

solvent is used

-

Powerful cleaning

Stubborn stains can be

also removed

POINT

Old-fashioned mold maintenance methods using organic solvents (mold cleaning sprays) involve the risk of health hazards.

Moreover, the separate cleaning of each part by hand for maintenance takes time and can cause variations in performance.

The CLIPIKA ACE contains no organic solvent so it can be used for the maintenance of molds with a sense of security.

In addition, multiple pieces of mold parts can be cleaned at the same time which can dramatically reduce the time taken for maintenance.

The frequency of the maintenance of molds can also be reduced which is expected to increase the utilization rate of molding machines.

- Introduction of CLIPIKA ACE products

-

The CLIPIKA ACE can clean multiple mold parts of various shapes at the same time.

- Risks of organic solvents

-

Organic solvents in mold cleaning sprays are harmful to the health.

Advantages

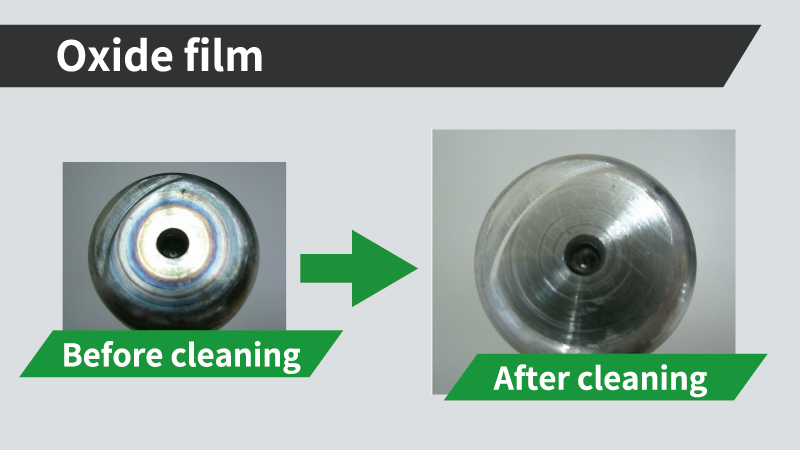

Cleaning ExampleDifferences between the CLIPIKA ACE and ultrasonic cleaning

Unlike cleaning machines using ultrasonic waves only, the CLIPIKA ACE can return molds to the same steel color as new with the synergy of electrolysis,

ultrasonic waves and cleaning solutions specified for the machine.

Comparison of the power

to clean gas burn marks (oxide films)

Even persistent stains, which cannot be removed by ultrasonic cleaning for 60 minutes, can be removed with the specified cleaning solution and the CLIPIKA ACE in the short time of 10 minutes.

Cleaning is safe because no organic solvents that are harmful to human health are used and electrolysis does not generate any hazardous gas.

Comparison of the power

to clean stains that are too small to be seen

Put a drop of water on a cleaned mold!

Extremely clean mold surfaces do not repel water and do not form water drops.

Ultrasonic cleaning leaves gas and stains infiltrated into the surface of molds although the surface may look clean.

When water is poured on the surface after ultrasonic cleaning, it is repelled and turns into drops because of the surface tension generated by impurities.

On the other hand, the surface of molds cleaned with the CLIPIKA ACE does not repel water which demonstrates that the machine has thoroughly removed all stains including those which are too small to be seen.

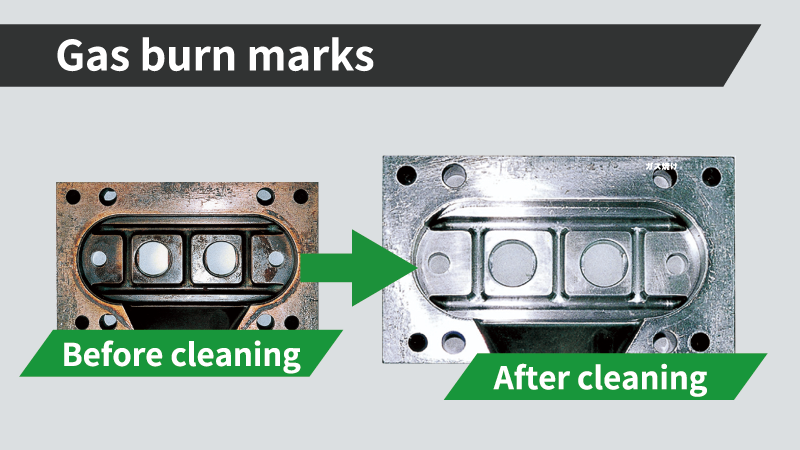

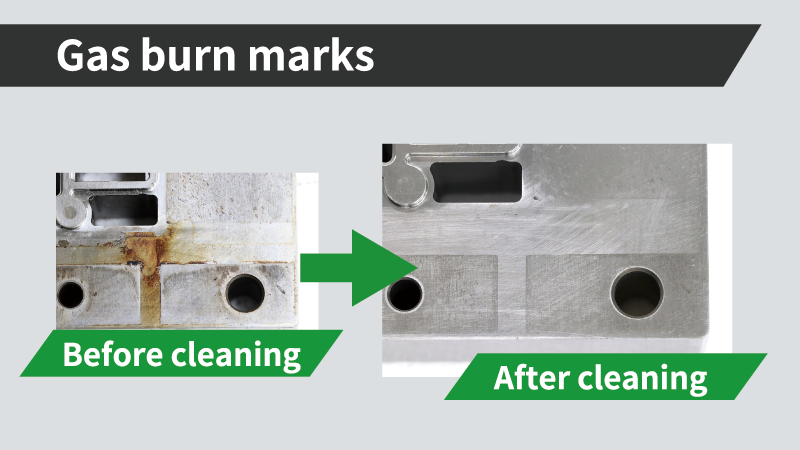

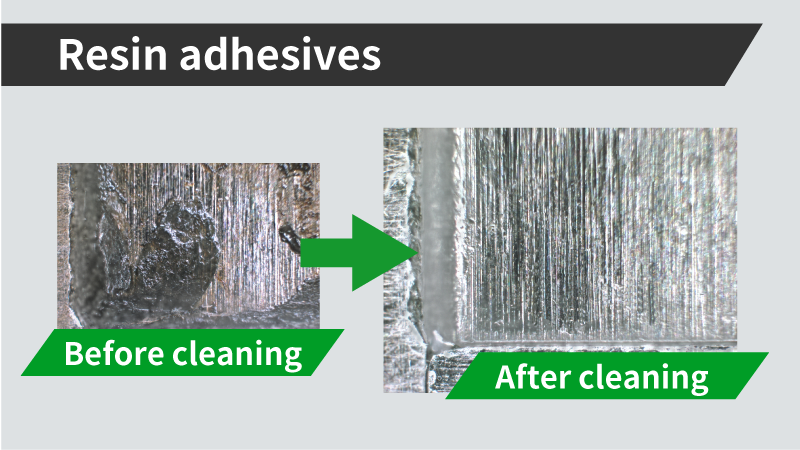

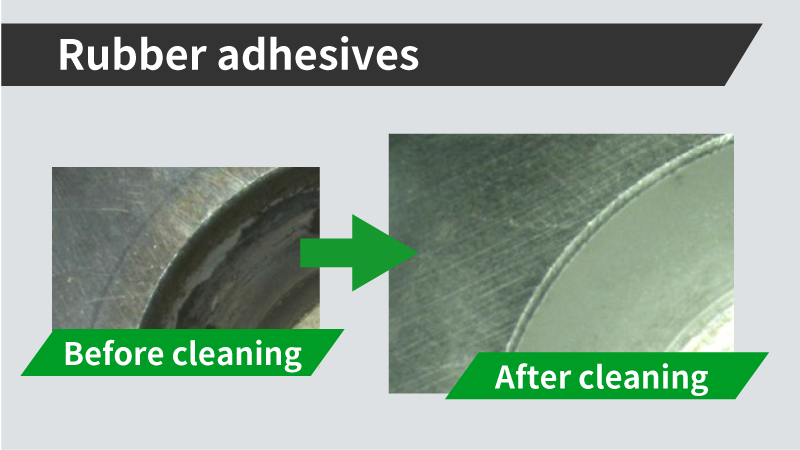

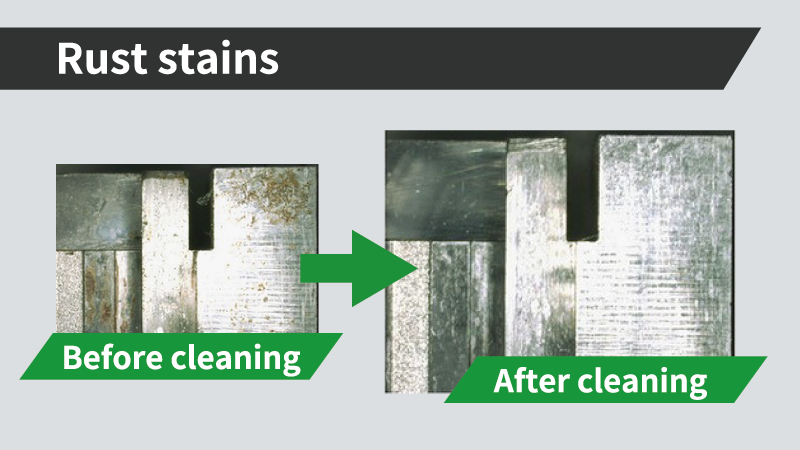

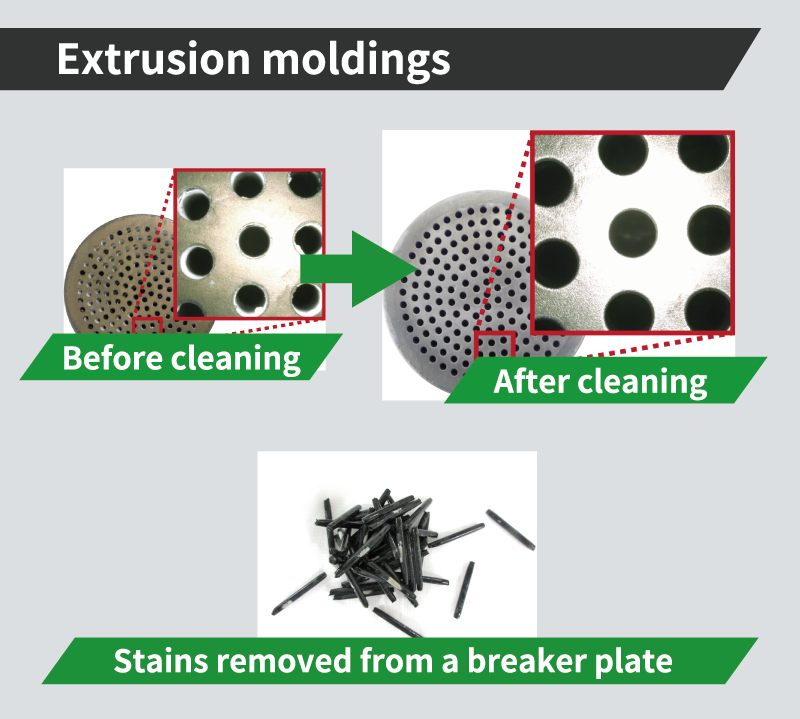

Examples of cleaning

Cleaning ExampleThe mold cleaning machine the CLIPIKA ACE supports high-quality molded items.

The following examples introduce its surprising cleaning power.

Catalog Download

Product Q&A

Product Q & AIn what industry is it used?

It is used extensively by plastic molding manufacturers, followed by mold manufacturers (about 70 percent in both industries). Besides the above, we have considerable experience to rubber molding, metal stamping and die-casting manufacturers.

What materials can be cleaned?

The machine is used for the cleaning of iron and steel molds but cannot clean molds made of copper, brass, aluminum or other metals.

What dirt can be removed?

It can remove not only gas stains or deposits and mold-releasing agent burns, but also gas burns (oxide film) and thin rust, unlike ultrasonic washing machines.

Does it affect molds?

It does not damage molds. No matter how many hours and how many times cleaning is repeated, there is no change in mold size or surface roughness.

Can mirror finished surfaces and embossed surfaces be cleaned?

It does not damage even mirror finished surfaces and embossed surfaces; therefore, they can be cleaned with confidence.

What about the cleaning process?

It comprises the following; Cleaning with the CLIPIKA ACE → Water washing → Soaking in the CLIPIKA COAT E (anti-rust treatment).

What cleaning solution is used?

An alkali cleaning solution specified for the CLIPIKA ACE.Our cleaning solution contains no organic solvent.

What is the difference between the CLIPIKA ACE and the CLIPIKA ACE OPT?

While the CLIPIKA ACE cleans ordinary iron and steel molds, the CLIPIKA ACE OPT is designed to specifically clean delicate molds for lenses, chemical solutions and other optical components. The latter is also applicable to common nickel-plated molds. The CLIPIKA ACE OPT has adopted creative ideas in cleaning solutions with optimal composition, the materials of the electrodes and the ultrasonic exposure method.

Is it sold outside Japan?

There are representatives in the United States, Mexico, South Korea, China, Taiwan, India, Thailand, Indonesia, the Philippines, Vietnam, Malaysia and other countries. In some countries, field demonstrations are available. Please contact us.

Lineup

LineupWe offer a wide range of CLIPIKA ACE products for different sizes of molds and different purposes.

Some of them also have a fully automatic cleaning function.

- CLIPIKA ACE III serieswith built-in heaters

-

■The temperature control heaters in the machine enhance the cleaning power.

■The machine can be operated with a sense of security with its multiple safety mechanisms.

■It uses no organic solvents and therefore causes no harm to human health or the environment.

■It cleans multiple pieces of mold parts at the same time to shorten the maintenance time.

■Even stains on PPS and POM that were considered to be not removable can be eliminated.

- CLIPIKA ACE Fully Automatic Cleaning Machine

-

■The operation of water washing, drying and corrosion prevention treatment is automated to save labor.

■The machine can complete the cleaning of molds while the operator is doing other jobs.

■The water used for washing is discharged after the pH is lowered to reduce its environmental impact.

■It cleans multiple pieces of mold parts at the same time to shorten the maintenance time.

■It uses no organic solvents and therefore causes no harm to human health or the environment.

- CLETOP

-

■The machine fully automates the operation of water washing, drying and corrosion prevention treatment after the cleaning of molds by the CLIPIKA ACE.

■It completes the whole process, from water washing to corrosion prevention treatment, in about 10 minutes even when multiple pieces of parts are handled.

■It can be operated with the basket for the CLIPIKA ACE used as it is.

■The water used for washing is discharged after the pH is lowered to reduce its environmental impact.

Products customized to meet customers’ requirements are available

Catalog Download

FreeRequest documents / Request for a demonstration

FreeRequest documents

Request for a demonstration

We support you with a demo machine

for free anywhere in Japan.

Online demonstration are also available for free!