Metal Mold Repair Welding Machine

MOLHEI

The MOLHEI is a welding machine that can easily repair very small molds.

The operator does not have to wear a face shield or mask because the machine generates no ultraviolet rays or welding fumes.

No qualifications or notifications on welding are required either as it is not subject

to the Ordinance on Prevention of Hazards Due to Specified Chemical Substances.

-

Easy to operate

Anyone can operate

it easily

-

Safety and security

No welding fumes

POINT

Conventionally, argon gas arc welding, which generates ultraviolet rays and welding fumes that are harmful to health, has been the most common method.

The MOLHEI generates no ultraviolet rays or welding fumes so the operator does not have to wear a face shield or mask. It allows the exact target point to be welded as no thermal shrinkage or deformation is generated, and the electrode is applied directly to the welding positions.

The machine requires no special skills, either, which enables molds to be repaired at the company.

- Introduction of MOLHEI

-

The MOLHEI requires no qualifications to use and enables anyone to repair molds easily.

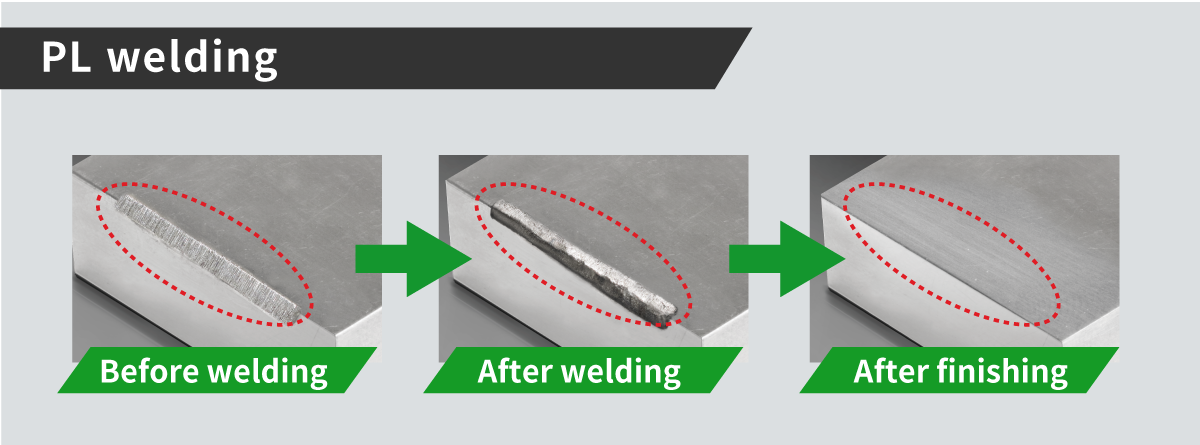

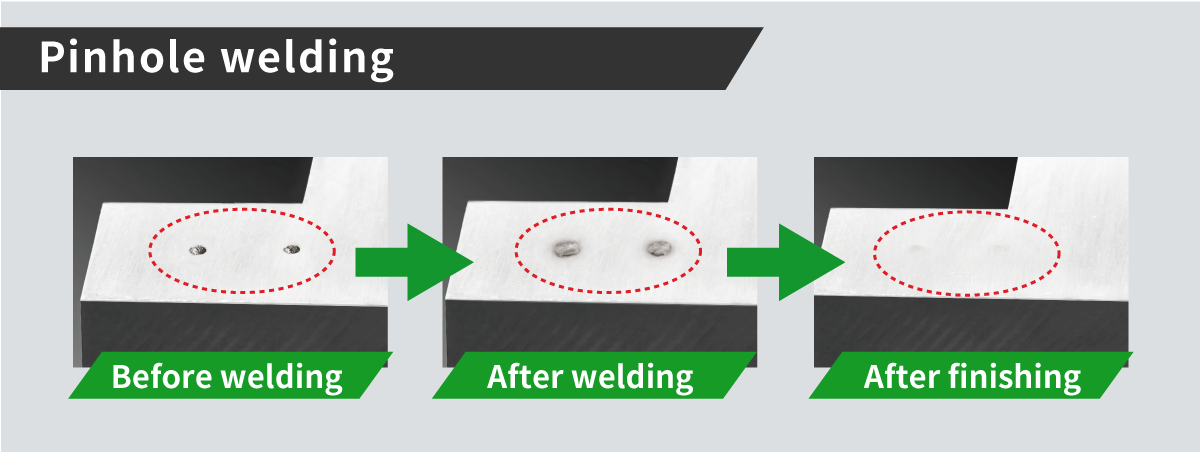

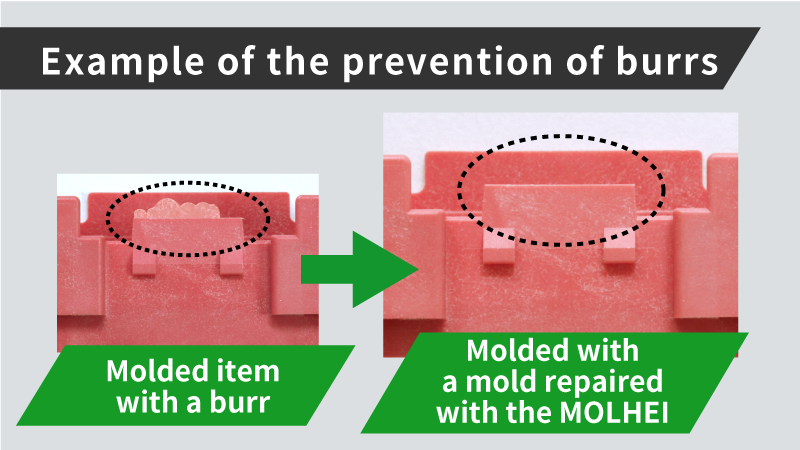

Examples of welding

Cleaning ExampleThe machine can be used easily and safely.

No shrinkage or deformation is generated and you can weld the exact target point.

Catalog Download

Product Q&A

Product Q & AHow is it different to argon welding?

The MOLHEI generates no ultraviolet rays or welding fumes so the operator does not have to wear a face shield. As the heat is not hot enough to melt the base material, the machine generates no thermal shrinkage or deformation and makes welding easy even without preheating or postheating. Welding on nitrided or chrome-plated molds is also available.

How is it different to spot welding?

While spot welding connects a point to a point, the MOLHEI can overlay linearly with continuous energization; therefore, it forms no cavities. In addition, it is outstanding for its overlaying speed and durability.

What mold materials can be overlaid?

The machine is used for the cleaning of iron and steel molds but cannot clean molds made of copper, brass, aluminum or other metals.

What about the welding procedure?

Everyone can overlay welds easily simply by applying metal cream to the welding parts and contacting an electrode to energize.

What hardness level is available?

Metal creams with a surface hardness of up to HRC50.

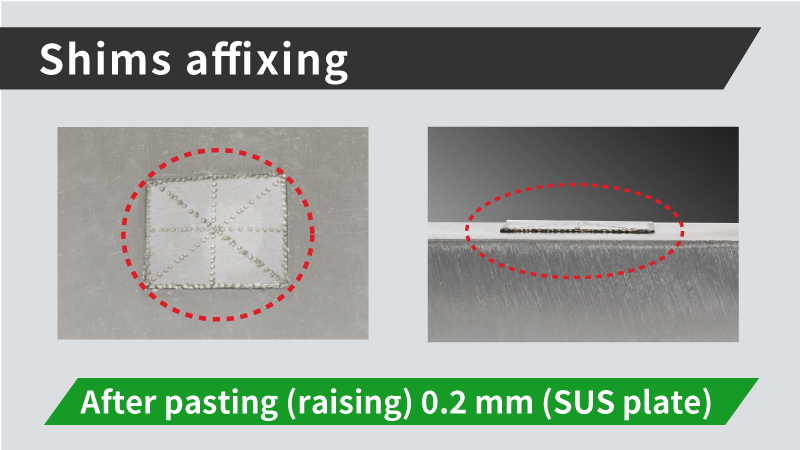

Can it also be used for affixing shims?

It can affix shims as thick as 0.2 mm by switching to the spot function.

Does the welding material "metal cream" for the MOLHEI contain cobalt?

Our welding material "metal cream" for the MOLHEI does not contain cobalt.

Is it sold outside Japan?

There are representatives in the United States, Mexico, South Korea, China, Taiwan, India, Thailand, Indonesia, the Philippines, Vietnam, Malaysia, and other countries. In some countries, field demonstrations are available. Please contact us.

Lineup

LineupProduct specifications of the MOLHEI are introduced below.

- MOLHEI

-

■The machine generates no ultraviolet rays or welding fumes that are harmful to human health so the operator does not have to wear a face shield.

■It generates no thermal shrinkage or deformation.

■It can be effectively used for a wide range of purposes such as overlay welding and shim bonding.

■The exact target point can be welded by keeping the electrode in contact with it.

■The compact design for welding at 100V enables the machine to be carried around easily.

Catalog Download

FreeRequest documents / Request for a demonstration

FreeRequest documents

Request for a demonstration

We support you with a demo machine

for free anywhere in Japan.

Online demonstration are also available for free!