ソマックス(株)にできること

金型は「ものづくり」の要であり、あらゆる業界に不可欠なものです。

金型洗浄液、金型洗浄機、金型温調配管洗浄機、金型補修用溶接機などの

金型メンテナンス機器の総合メーカーであるソマックス株式会社は、

日本だけでなく世界の「ものづくり」をメンテナンスの面から支えています。

ソマックス株式会社の強み

Strengths

金型メンテナンスを研究し

30年以上

業界32%のシェア、

累計販売総数

8,000台以上の実績

研究・開発・製造・販売・販売促進資料の

企画及び作成をすべて社内で行っている

金型洗浄液と金型メンテナンス機器の全てを一貫して自社で研究・開発・製造・販売しているからこそ

現場が抱える多くの「困った!」をワンストップで解決し、合理的でサスティナブルな

金型メンテナンスに貢献できるのです。

「ものづくり」を支える、

当社の主力製品

Supports manufacturing「ものづくり」企業様の

さまざまな課題を解決!

Action & Problem Solving-

樹脂射出成形企業様向け

課題

腐食性物質である可塑剤を含む成形ガスが金型を錆びさせ、

放置しておくと錆がどんどん進行し広がり深くなってしまい金型の寿命を縮める。 -

ゴム成形企業様向け

課題

ゴム金型は、ゴムカスや腐食に繋がる加硫ガスのクリーニングが欠かせません。

しかし、高温のアルカリ洗浄剤とブラッシングだけでは、溝や穴などは言うまでもなく、

金型表面に染み込んだ腐食性の汚れの洗浄が不十分。また、アルカリ洗浄剤の蒸気が身体におよぼす影響が心配。 -

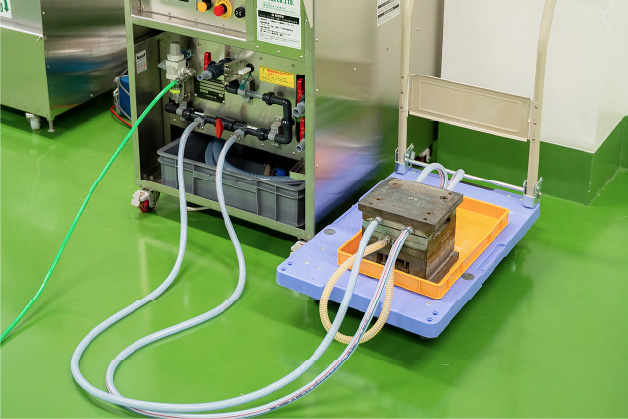

ダイカスト企業様向け

課題

金型の冷却効率が低下し、焼けつきや“ス”などの鋳造不良やピン折れやクラックなどの金型故障が増えてきた。

解決

金型温調配管用洗浄機スカットスは、60リットルの大容量槽で大型金型の温調配管内の

製品情報を見る

錆やスケールを根こそぎ取り除き、冷却効率を改善します。

また、除錆と同時に一次防錆被膜を張るので予防保全に最適です。 -

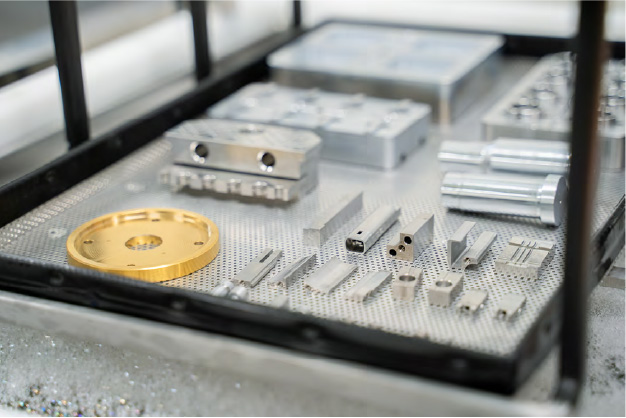

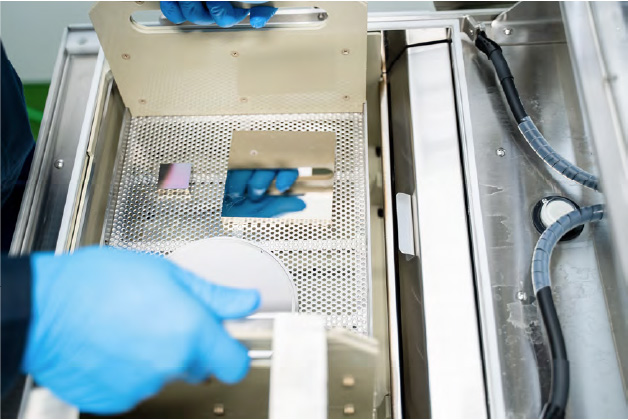

金属プレス企業様向け

課題

油の焼きつけや錆が広がり深くなっていくので金型の動きが悪くなり金型もどんどん磨耗していく。

広がり深くなっていく錆を磨き落とすも金型部品の点数が多く、掃除に時間がかかる。解決

金型洗浄機クリピカエースでたくさんの金型部品をまとめて一度に洗浄すれば、

製品情報を見る

メンテナンス時間を大幅に短縮できます。

また、焼きつきや広がり深くなっていく錆を擦らず除去するので金型寿命も延びます。